InfraShield® Seismic Resilient Joint System

Seismic Resistant Joint System for C200 Steel Pipe

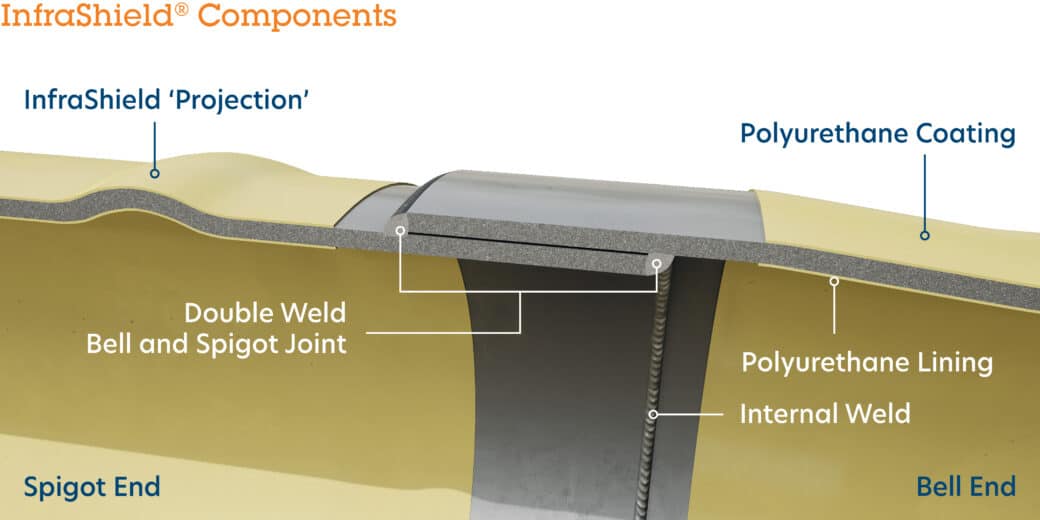

It started with the simple idea that seismic resilient steel pipelines need not be complicated, tough to install, or expensive. The InfraShield® Seismic Resilient Joint system realizes this idea with a straightforward yet effective design. The patent-pending technology developed by our engineers builds on the proven performance of C200 steel pipe with bell-and-spigot lap-welded joints. We designed a small projection in the pipe wall that provides even greater resilience and sustainability during a seismic or geohazard event. The steel pipe stretches and folds while protecting the joint, allowing the pipe to continue delivering life-saving water to first responders and communities after an event.

In addition to the ease of installation, reliability, and cost advantages compared to other options, the InfraShield® system can be used in locations that were once thought to require the ‘oil and gas type pipe’ with thick walls and butt welds. Compared to this antiquated pipe style, InfraShield® has lighter-weight pipe walls and directs any event impact to occur at the spigot end of the pipe without reducing the structural strength of the joint or thinning the pipe wall.

Quick Installation and No Additional Costs

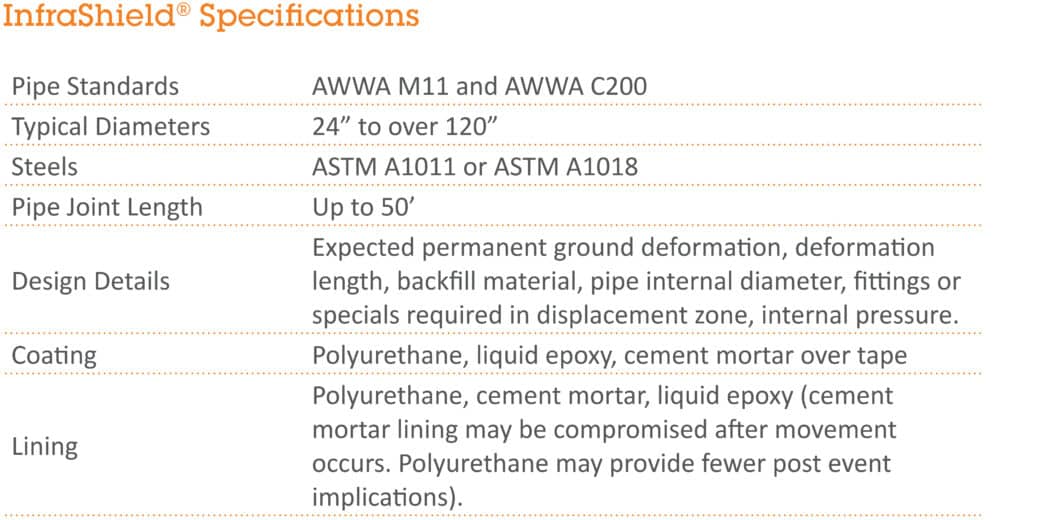

From a contractor’s perspective, InfraShield® installs no differently than C200 pipe with a bell-and-spigot lap weld joint, polyurethane coating, and either polyurethane or cement mortar lining. Our resilient solution requires no additional training, supervision, or specialized tools. This means quick installation with no added installation costs or risks. The resilient nature of steel pipe also delivers joint soundness without perfect trench grading or soil stability. Other seismic resilient systems require special field crew training, installation oversight from the manufacturer, or even overseas delivery that slows down field teams and raises costs significantly.

Manufactured & Tested for Resilience

Northwest Pipe’s InfraShield® Seismic Resilient Joint System has undergone rigorous performance testing. Our engineers tested the joint options in numerous scenarios to simulate a seismic event, differential settlement, landslide, and liquefaction hazards. Specific to this testing, we built two large presses at our Adelanto plant that bend, compress, and stretch joined C200 steel pipe to measure mechanical performance under severe structural bending and axial (compression and tension) loading. In addition to our full-scale physical testing, the InfraShield® performance concept is proven by extensive finite element analysis and reported in numerous technical papers prepared for the UESI Pipelines Conference.

Made in the USA, the InfraShield® system meets the Buy America program provisions. Its resilient construction maintains watertight integrity and can withstand multiple shocks and after events, and unlike PVC or HPDE pipe, repair locations are easy to identify. The system can be used in conjunction with other pipeline, and design teams may opt to spec InfraShield only in potential differential settlement, landslide, liquefaction, or geo-hazard zones.