Geohazard Resistant Joint System for C200 Steel Pipe

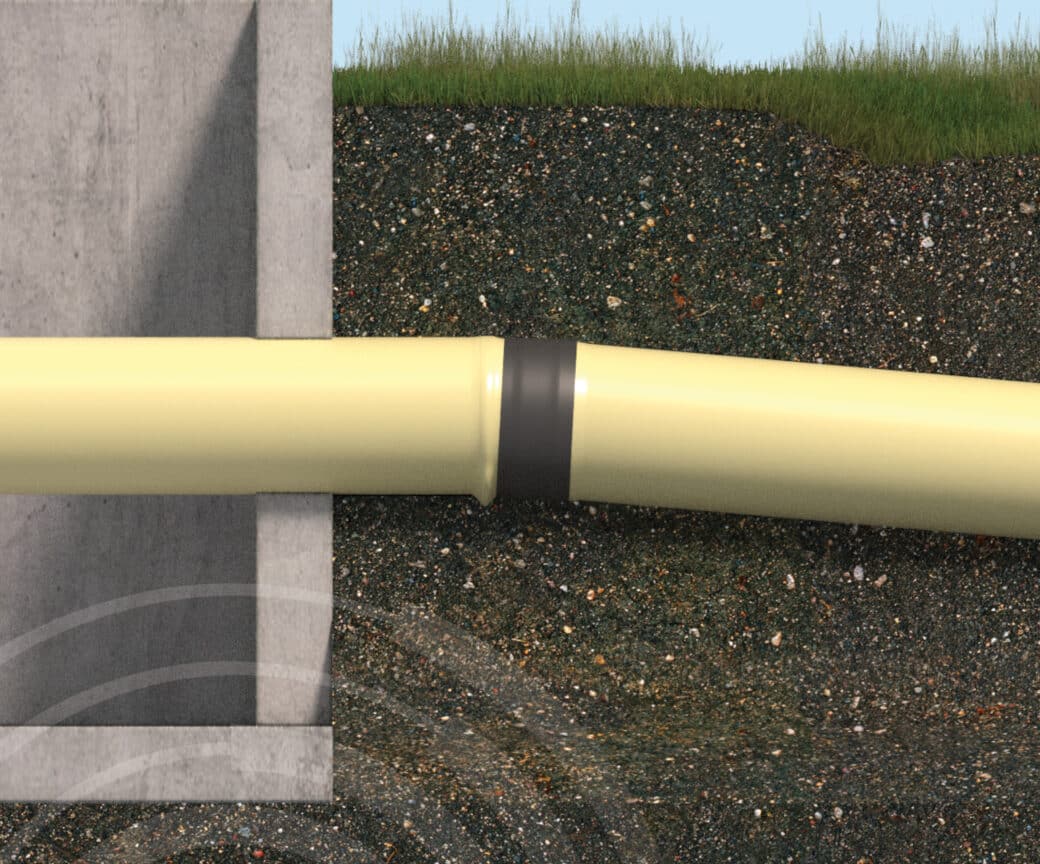

In areas prone to geohazard conditions, such as differential settlement or high seismic activity, resilient water infrastructure is paramount to ensuring a reliable supply of clean and safe water for communities and first responders. The InfraShield® Joint System by Northwest Pipe Company is a patented Geohazard Resistant Steel Pipe (GRSP) solution designed to effectively strengthen the resilience of steel pipelines and keep water flowing in these vulnerable geological areas. Manufactured in the USA and backed by rigorous testing, InfraShield® is a fully welded, easy-to-install system that offers reliably leak-free performance and significant cost savings.

Manufactured for Resilience

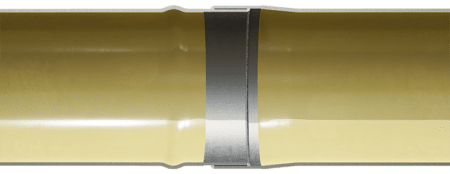

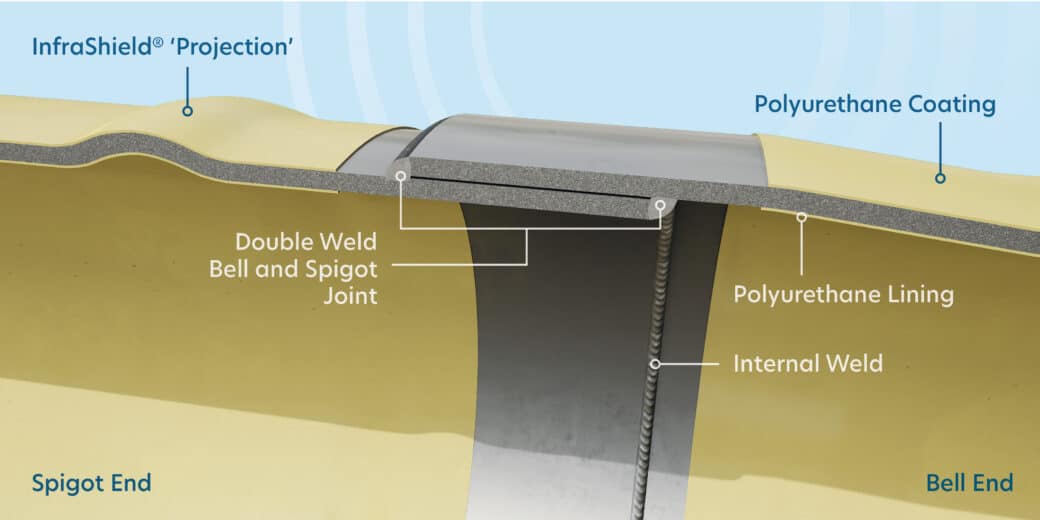

The InfraShield® Joint System technology builds on the proven performance of C200 steel pipe with a standard bell and spigot lap welded joint to provide even greater resilience in geohazard zones. Previously, couplings or joints with seated gaskets were typically used to maintain water containment after expected soil settlement or major seismic events. However, complex installation and the potential for leaks in gasketed connections can increase risk and threaten reliability. InfraShield’s innovative, patented joint design eliminates the need for gaskets, providing a fully welded, leak-proof system that ensures uninterrupted water delivery to critical infrastructure and communities.

Simple & Effective Design

Simple & Effective Design

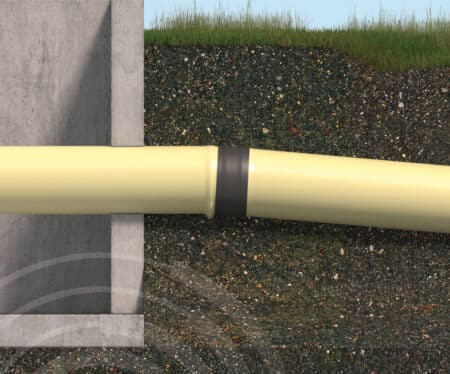

The InfraShield® Joint System utilizes a strain-based design to enhance the resiliency of lap-welded steel pipe. A small projection is manufactured into the steel pipe wall which effectively absorbs deformation imposed by differential settlement or seismic activity without over-stressing the lap-welded joint itself. Extensive full-scale physical testing and finite element analysis has verified the integrity of the InfraShield® Joint System.

From an installer’s perspective, InfraShield® installs no differently than C200 pipe with a bell and spigot lap weld joint. It requires no specialized training, tools, or supervision. This means quick installation with no additional costs or risks.

Its resilient construction maintains watertight integrity and can withstand multiple shocks and after events, and unlike PVC or HPDE pipe, repair locations are easy to identify. The system can be used in conjunction with other pipeline, and design teams may opt to spec InfraShield® only in potential differential settlement, landslide, liquefaction, or geohazard zones.

InfraShield® Components

100% American Made

The InfraShield® Joint System improves the mechanical response of lap-welded joints by introducing a small projection around the pipe circumference at the spigot side of the weld. This enhancement forces any deformation to occur at the projection, thereby protecting the lap weld joint. Made in the USA, the InfraShield® Joint System meets the Buy America program provisions.

Advantages

Quick Installation

InfraShield® installs like any C200 steel pipe with bell-and-spigot lap weld joints—no special training or equipment required. It’s a contractor-friendly system that saves time in the field and minimizes risk.

Cost Savings

Simple installation translates to lower construction costs, especially compared to alternative systems that require additional crew training and installation oversight.

Proven Performance

The InfraShield® Joint System has been verified with rigorous, full-scale physical testing backed by extensive finite element simulations.

Reliably Leak-Free

InfraShield’s fully welded, gasketless design provides a high-strength watertight connection, delivering joint soundness without perfect trench grading or soil stability. Our leak-proof joint system guarantees continuous water delivery without the need for system redundancy.

Applications

MoreDifferential Settlement

• Subsidence

• Expansive or soft soils

• Replace leaking joints or couplings

Major Seismic Events

• Earthquakes

• Fault Crossings

• Landslides

• Liquefaction Hazards

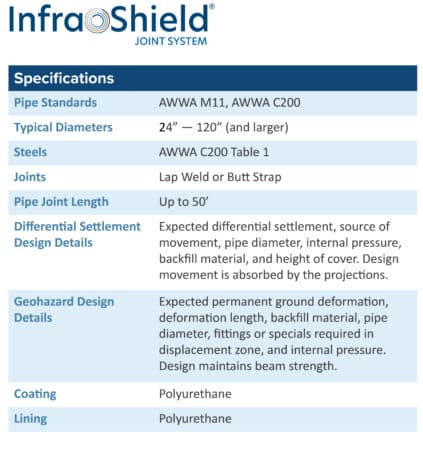

Specifications