Keeping Our Cool: How the NWP Team Stays Safe in the Summer Heat

Preventative Measures in Place for Warm Weather at Our Manufacturing Plants

It’s the official start of summer—time to fire up the barbecue, get out the camping gear, slather on some sunscreen, and brace for the summer heat. Temperatures are already rising, hitting 90+ degrees across the U.S. While the warmer weather may be ideal for outdoor recreation activities, it can make for more strenuous working conditions, especially for those not used to the heat. At Northwest Pipe Company, we’re taking precautions to ensure all team members are staying safe from heat-related hazards.

Each of our manufacturing plants has a detailed heat-illness prevention program in place that assesses risk factors, specifies preventative actions, and outlines an emergency response plan. The local safety representative is responsible for administering the program, including conducting initial training for team members and monitoring the OSHA heat index for current conditions. Plant management and department supervisors support ongoing training and daily implementation of procedures. Training emphasizes awareness of each individual’s response to heat and attention to others by watching for symptoms of heat-related illnesses like heat exhaustion or heat stroke. According to the National Institute for Occupational Safety and Health (NIOSH), symptoms may include:

Heat Exhaustion

- Headache

- Nausea

- Dizziness

- Weakness

- Irritability

- Thirst

- Heavy sweating

- Elevated body temperature

- Decreased urine output

Heat Stroke

- Confusion, altered mental status, slurred speech

- Loss of consciousness (coma)

- Hot, dry skin or profuse sweating

- Seizures

- Very high body temperature

Emergency first aid and medical treatment are necessary for individuals experiencing either of these heat-related conditions. Alertness to the warning signs and taking immediate action to ensure proper treatment of symptoms is critical, but the goal is to avoid heat stress in the first place.

Prevention is Key

Heat stress is preventable, but it takes vigilance and preparation to keep cool in an industrial manufacturing environment during the hottest months. The critical components of heat safety at our facilities are designed to encourage hydration and provide cool spaces to recharge.

Hydration Stations

Drinking enough water every day is important regardless of the temperature outside, but it’s even harder to stay hydrated when working in the heat. Consuming adequate amounts of water and electrolytes is critical to keeping cool and avoiding dehydration. According to NIOSH, workers exposed to heat should drink about eight ounces of fluids every 15-20 minutes. The following are some of the hydration options available to our team members in their work areas:

- Ice water coolers (replenished throughout the day)

- Electrolyte water/powder mix or sports drinks (sugar-free options)

- Electrolyte popsicles/freeze-pops

Cooling Spaces

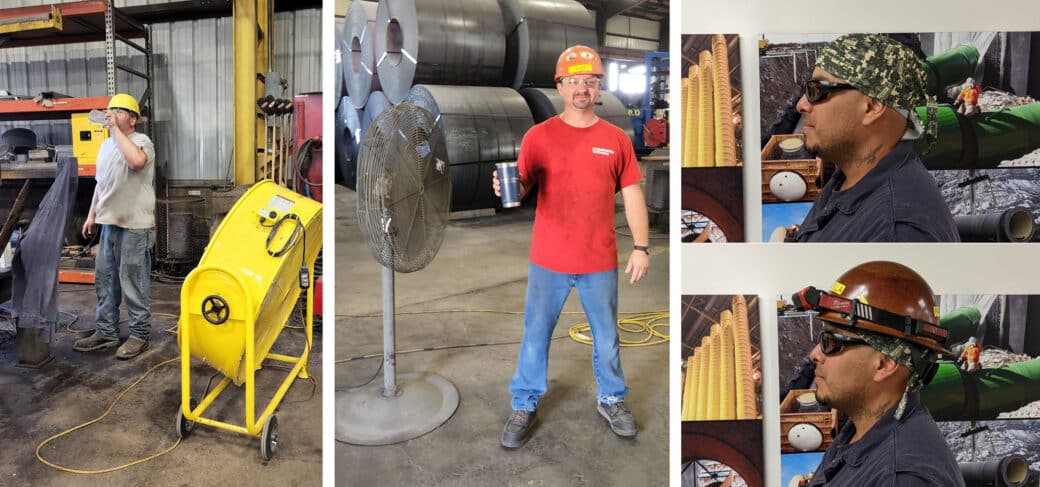

Limiting time in the sun and taking breaks from the heat throughout the workday is essential to avoiding heat overexposure. To give team members working outdoors or in hot environments the opportunity to cool down, our plants have designated rest areas with overhead shade or AC available. Multiple fans are set up throughout the facilities for airflow.

Depending on local conditions, some plants have additional measures in place. For example, neck-cooling towels are available at our Permalok plant in St. Louis, Missouri. In Saginaw, Texas, where ambient temperatures hit 90 degrees in April this year, the team installed misting fans in outdoor working areas and indoors in enclosed canopies. In SLRC, Mexico, temperatures can hit the triple digits six months out of the year, so our local manufacturing plant has purchased aero coolers (portable air conditioning units) and cold beverage refrigerators. Additionally, each employee at SLRC is provided with an insulated water jug for use at work.

Hot Weather Attire

Wearing proper seasonal work attire can help limit heat exposure. At the SLRC and Saginaw plants, nape covers are installed on helmets to keep the sun off employees’ necks while working outside. In Portland, employees are provided with cooling triangle hats (evaporative cooling bandanas) to wear under their safety helmets during the warmest months.

Acclimatization

When summer weather first arrives and temperatures suddenly skyrocket, it can come as a bit of a shock to our systems. The same goes for new employees not acclimated to working in hot conditions. The good news is that individuals can become safely accustomed to working in warmer weather by following the heat acclimatization plan outlined by NIOSH, which involves gradually increasing work intensity/duration in the heat over a 1-2 week period. Acclimatization increases your ability to perform physical tasks in the heat; it can also cause you to sweat more—a positive sign that your body is efficiently cooling itself, and meaning you will need to drink more water to recover fluids.

The Human Factor

The OSHA heat index, which factors outdoor temperature and relative humidity, is used to assess the levels of caution required to avoid heat stress depending on the day’s weather conditions. But, another important consideration in heat safety is the human factor. “You can’t always go by ambient temperature,” says Les Lowe, Safety & Environmental Manager at our engineered steel plant in Saginaw, Texas. “It’s not all about facts and figures, it’s about people. Only you can know how your body is feeling in the initial stages of heat exhaustion.”

Recognizing the early signs of heat exposure and treating them accordingly with water, shade, and rest is key to staying safe, but the best solution is prevention. “Keeping your body hydrated will help in a lot of ways. Don’t wait until you’re thirsty. If you start drinking water when you’re already thirsty, it’s too late,” says Les. By utilizing the hydration and cooling options provided at each facility, and embodying the Northwest Pipe values of Teamwork and Accountability to watch out for one another, the NWP team is committed to beating the heat and staying safe this summer.

>

>