Joints

Delivered to your jobsite with an integrated interlocking joint, Permalok® steel casing pipe eliminates time-intensive field butt welds in trenchless pipe installation projects. The precision-machined interface is flush with the interior and exterior surfaces of the pipe for quick alignment and connection. Combined with the use of a silicone sealant, the Permalok joint is leak resistant under the most challenging conditions.

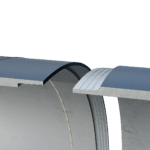

Permalok® T-5 Joint

The flagship T-5 joint is used most often and maintains integrity with typical loading conditions for casing pipe. It is well suited to both compression and bending in applications involving microtunneling, pipe jacking, pipe ramming, and auger boring. We machine the joint profile to tolerances of less than +/- 0.005” and maintain consistent quality and integrity. A sealant lubricates in the grooved profile of the connection creates a water-resistant seal.

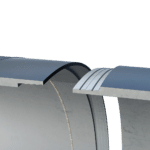

Permalok® T-7 Joint

The Permalok T-7 joint features a precision-machined interference fit similar to the T-5 joint, but incorporates two rubber O-Ring gaskets. Permalok pipe with a T-7 joint can be used as a carrier pipe in low- to medium pressure applications or in conjunction with a seal pass weld for low- to medium-pressure applications. The pre-installed joint facilitates rapid stabbing and alignment resulting in a joint connection that is flush with the interior and exterior surfaces of the pipe.

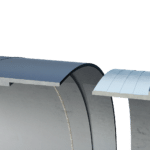

Permalok® AB Joint

The Permalok® AB Joint is one of the latest innovations in steel casing pipe. We incorporated feedback from auger bore contractors to create the AB Joint, which provides the same great benefits as the legacy products, while allowing for a direct push installation and lower connection forces to help mitigate some of the challenges associated with auger bore installation. The AB joint is not exclusively limited to auger bore installations, but the lower costs performance can only be realized by Permalok.

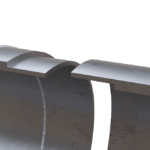

Permalok® CC Joint

The Permalok® CC (Cycle Casing) Joint is a reusable steel casing tool for Pilot Tube Guided Auger Boring (PTGAB) applications. The CC is specially designed to upsize pilot tube or auger bores through a cycle process to the final casing size. Utilizing a ‘slip joint’ style profile, our Cycle Casing easily connects without welding and can be taken apart at the exit pit with zero cutting, breaking, or refinishing required. It can be used in conjunction with any product pipe, and is optimally paired with the AB Joint as part of our Quick Bore System.

Permalok® PR Joint

The Permalok® PR joint is created specifically for pipe ramming. We teamed with pipe ramming contractors and equipment manufacturers to address the concerns of energy transfer loss during ramming a mechanical joint, which typically resulted in a jacking limitation of less than 200 linear feet depending on soil conditions. The Permalok® PR joint utilizes a proprietary negative interference fit connection to capitalize on the mechanical properties of the material to reduce energy transfer loss during ramming operations. The result is longer drives without welding, enabling teams to complete pipe ram projects faster than ever.

Permalok® HDD Joint

The HDD Joint connects sections of pipe 12″ in diameter and under using a Drill Rig. The Type HDD profile incorporates an additional locking key on the male portion of the joint to increase pull-apart resistance while requiring less force to complete the joint makeup. The HDD profile is longer and more flexible. By increasing the joint length, the spacing between interlocking ribs is greater, increasing connection speed and ease. With the Permalok® Type HDD profile, contractors can install steel pipe from the rig side of the bore path, using the drill rig to make up the sections and advance them, similar to installing drill stem.

Permalok® Radial Bending Joint (RBJ)

The patent-pending Permalok® Radial Bending Joint (RBJ) enables steel pipe to be installed along a curved radius in microtunneling applications. This advancement provides additional maneuverability in congested tunnel alignments, allowing the pipe path to bend in any direction.