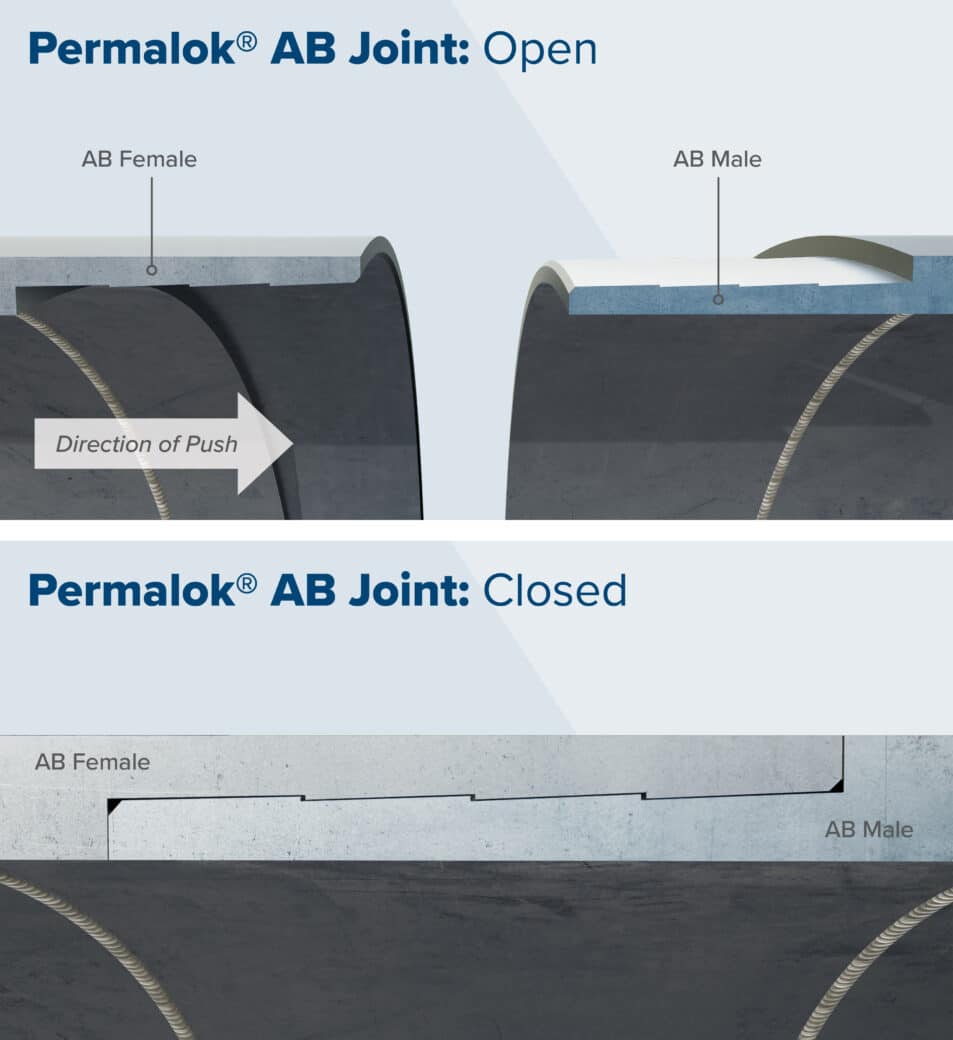

Joint Detail: Permalok® AB Joint

Increasing Productivity and Minimizing Risks for Auger Bore Installations

The Permalok® AB Joint, or Auger Bore Joint, is one of the latest product innovations advancing the field of trenchless technology. Incorporating feedback from contractors’ most challenging auger bore projects, the patented AB Joint features an interlocking push joint design that eliminates the need for butt-welding in the field. The result? Increased installation productivity, minimized risks on tough-to-access pipeline projects, and substantial project cost savings.

Design and Manufacturing

The Permalok® AB Joint utilizes a precision-machined interference fit that eliminates the need for time-sensitive field applied butt-welds on trenchless and open-cut applications. The pre-installed joint connection is flush with the interior and exterior surfaces of the pipe, allowing for quick, easy, and permanent joining of each steel casing pipe piece in a project. Its unique stepped profile makes stabbing and aligning simple and expeditious.

With a proven track record of over 30 years, Permalok® manufactures steel casing pipe to the tightest tolerances and highest quality standards in the industry. Permalok® pipe is produced to AWWA or ASTM standards, and the AB Joint’s unique profile is machined to tolerances of less than +/- 0.005 of an inch, which creates a joint of consistent quality and integrity. Available in diameters from 8” to 156” and wall thicknesses up to 2.5”, Permalok® can be manufactured in custom lengths to maximize the efficiency of your project. Permalok® also offers a wide range of coatings and linings to meet the most difficult project specifications.

Flexible Application

Building upon the proven technology of the legacy Permalok® products, the AB Joint reduces the connection force required to fully engage the joint by 2.5 times, making this joint ideal not only for auger boring, but for low resistance jacking and critical time path open-cut applications.

Quick and Easy Installation

The Permalok® AB Joint allows for a direct push Installation with flush ID and OD surfaces in which the auger flighting can be installed within the pipe prior to fit up, increasing productivity and throughput. The AB Joint provides contractors with added steerabilty over welded casing, supporting inline adjustments and successfully countering boring challenges to more consistently meet tight line and grade requirements. When used in conjunction with Pilot Tube installation methods, Permalok® provides measured repeatability and risk management.

The Permalok® AB joint installs in reverse of traditional pipe, with the female installing over the male. We make it easy to identify the proper installation direction by including an arrow on the exterior of each pipe.

AB Joint in Action

The Permalok® AB Joint excels in the toughest installation environments, offering a solution for contractors working with space restrictions and challenging soil conditions. Such challenges faced the crews working on the CalTrans Weaverville State Route 3 Culvert Rehabilitation Project. With limited lay down and construction area, and soils primarily made of glacial till, the Permalok® AB joint proved an effective method of installing the seven parallel bores necessary to repair a series of deteriorating culverts.

The project utilized 760 feet of 36-inch Permalok® steel casing pipe with AB joints in combination with 110 feet of 60-inch Permalok® with T-5 joints, successfully installed at a rate of 150 LF per shift within ¼-inch of grade. The AB Joint allows a straight push on the pipe reducing the impact of trying to manage both the internal auger fighting and the pipe connection in the confined space.

>

>