The Permalok® HDD Joint is a direct push system specially designed to optimize Horizontal Directional Drilling (HDD) operations. Typically, an HDD set-up requires a substantial footprint, including a rig/operating area, reception area, and a stretch of open land for laying out the pipe string. The cost of equipment, including rollers, cranes, and excavators, as well as the labor to operate them, quickly add up. Our HDD joint eliminates the need for pipe string-out, reducing the project footprint and associated construction costs.

Utilizing direct push to engage joints rather than the pull technique traditionally used in HDD applications, the Permalok® HDD system quickly and easily installs using existing equipment, and without the need for welding. It can be pushed from the shoreline or beach without the need for additional water crews or specialized tools. Our HDD joint provides the same allowable bend radius as a standard HDD installation (100 ft/OD in per ASC MOP 108). Engineered with the precision and durability guaranteed in all Permalok® products, our HDD joint offers a high-quality and cost-effective piping solution for even the most challenging HDD applications.

Award-Winning Innovation

The Permalok® HDD Joint has earned multiple industry honors, including NASTT’s Innovative Product of the Year. It was also featured in Trenchless Technology’s Project of the Year – New Installation for its role in the Champlain Hudson Power Express Project, where it was successfully installed in a 5,200-linear-foot dual crossing beneath New York City’s East River.

How it Works

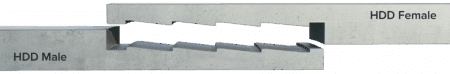

The Permalok® HDD Joint quickly and efficiently connects sections of steel product pipe from the drill rig side of the bore path. It utilizes the drill rig to connect and advance pipe sections similar to drill stem, eliminating the need to string pipe or weld joints together. The joint profile incorporates an additional locking key on the male connection side to increase pullapart resistance while requiring less force to push joints together securely.

Sizes & Specs

Available in 8” – 156” diameters with wall thicknesses up to 2.5,” Permalok® can be manufactured in custom joint lengths to maximize the efficiency of your project. Permalok® also offers a wide range of coatings and linings to meet the most difficult project specifications.

Proven Performance

Northwest Pipe Company supplied over 10,000 feet of 20-inch steel casing pipe with Permalok® HDD Joints for the final segment of the Champlain Hudson Power Express Project—named Trenchless Technology’s 2025 Project of the Year – New Installation. The use of the press-fit Permalok® Joint enabled the HDD method to be completed within a smaller jobsite footprint and in a congested urban environment, eliminating the need for pipe string-out or field welding.